This tester was designed primarily for testing instant water heaters on a production line. It can also be used to test other kinds of heating or cooling related appliances such as storage type water heaters, air-conditioners, electric kettles and other home appliances. The parameters tested are :

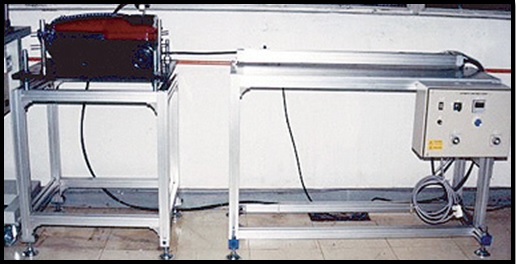

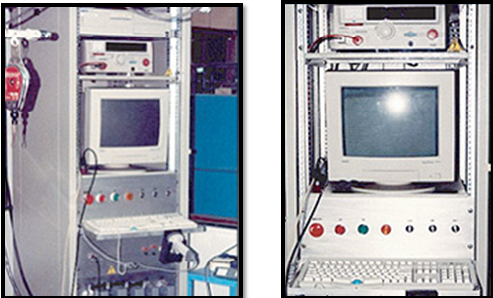

The tester has 2 main parts. Figure 1 shows both parts. On the left is the control and measurement rack, which is a standard 19-inch rack. It houses (from top to bottom) the Safety Tester, a 15-inch monitor, a power control panel, a keyboard, a sub-rack that houses the measurement and control cards, a contactor and relay bay, and of course at the bottom is the PC.

On the right is the test fixture. It has been constructed of extruded aluminum. You can see (top center) a white bodied water heater ready for testing. To the left of the water heater are the operator interface switches & indicators. The operator uses these switches to start & stop testing, load & unload units for testing. LEDs above these switches indicate to the operator the status of the test. The yellow hose at the bottom is the incoming water supply and to its right, the black colored devices are solenoid activated water flow control valves.

.jpg)

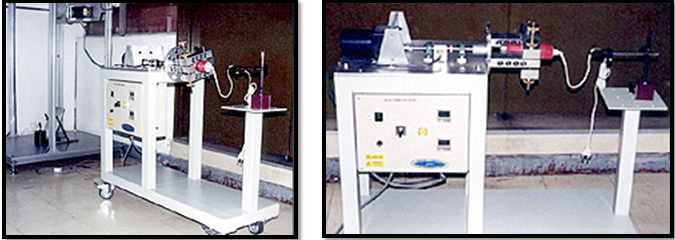

The crocodile clip with the red wire has been connected to a live part. This is to enable a ground fault current to be generated during the ELCB function test. This test verifies the proper operation of the built-in ELCB .

The crocodile clip with the green wires attached to it has been connected to the copper casing of the heater. This clip will carry the Ground Continuity Test current (15A). The second green wire connected to the same clip is used for 4-wire measurement of the voltage across the ground connections.

The water connections have not been made. This will happen when the pneumatic cylinder below the two brass posts is extended upward.

The pneumatically operated incoming power supply (AC Mains) adaptor has been fitted onto UUT (Unit Under Test).

.jpg)

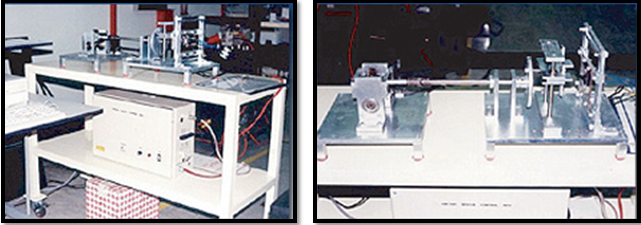

A set of 4 vacuum pads are used to hold the unit under test firmly in place during testing. These pads are connected to a vacuum generator, that can be toggled on and off by the operator using a pushbutton switch on the operator interface panel. The crocodile clip connected to the red wire will be clipped onto a live part in the UUT to generate a controlled earth current fault for testing of the UUT's built-in ELCB.

The crocodile clip connected to the green wires will be clipped to an exposed, grounded metal part of the UUT to aid in the testing of the ground connections. At the center of the bottom half of the picture, you will notice two brass posts mounted on a plate which in turn is mounted on a pneumatic cylinder. The hollowed out brass posts enable water in and water out connections to be made to the UUT conveniently. Embedded RTD probes measure the temperature at both inlet and outlet. Before water is turned on, the brass posts are moved up towards the UUT by the automatic activation of the pneumatic cylinder.

.jpg)

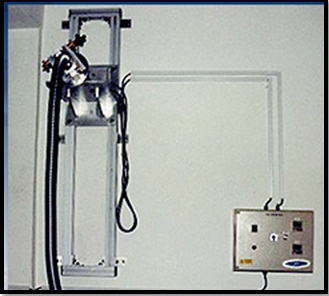

This is the 19-inch, 6U height sub-rack that holds the test cards. It is mounted just below the keyboard in the 19-inch main rack. There are two backplanes, the Digital back plane and the Analog backplane.

Housed in the sub-rack are the digital circuit power supplies (right hand side of the sub-rack). Also housed is a step down transformer for the analog power supplies. It is not visible in this picture

.jpg)

The water flow control system consists of the following main parts :

.jpg)

.jpg)

Typical applications include :

.jpg)

4 Channels of Temperature Measurement using RTD (PT100 or other)

2 Channels of F-V Converter (RPM, Flow Rate, Frequency Measurement etc)

Input ranges :

.jpg)

0 - 150 Volts (AC & DC)

0 - 300 Volts (AC & DC)

0 - 200 mAmps (AC & DC)

0 - 20 Amps (AC & DC)

0 - 3000 Watts

0 - 6000 Watts

Outputs :

Output Conversion Factors :

0 - 150 Volts RMS to 0 - 7.000 Volts DC

0 - 300 Volts RMS to 0 - 7.000 Volts DC

0 - 200 mAmps RMS to 0 - 7.000 Volts DC

0 - 20 Amps RMS to 0 - 7.000 Volts DC

0 - 3000 Watts RMS to 0 - 7.000 Volts DC

0 - 6000 Watts RMS to 0 - 7.000 Volts DC

Accuracy - + / - 0.5 % of input range

Typical applications :

4.5 Digit Precision Integrating Analog To Digital Converter

.jpg)

0 - 1.9999 Volts

0 - 19.999 Volts

0 - 199.99 Volts

Optically isolated from back plane

Hi-Pot / Insulation Tester Control and Ground Continuity (Earth Bond) Test Card

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Using infrared rays to heat up thermostats and then cooling them with pressurised air, these thermostat testers exercise thermostats that are normally built into rice cookers, thermo pots, slow cookers etc.

The chart recorder on the top will record the opening and closing temperatures of the specimens under test.

Designed for a leading electro-plating company, this rectifier is capable of producing up to 150 Amperes of constant current with a maximum compliance voltage of more than 12 Volts.

It is ideal for 24 Hour electroplating operations or other areas where a reliable source of current has to be supplied. If not used as a current source, it can also be configured as a voltage source.

Built-in protection includes over current, over temperature and short-circuit protection.

Capable of testing nine sets of completed electric iron sole plates concurrently, this tester measures, records and compares sole plate performance against set limits. Using a non-contact type of temperature sensing head and a Fluke HYDRA it can capture parameters such as maximum temperature, minimum temperature and overshoot temperature for any number of cycles.

An on-screen display not only informs the operator of the progress of the tests, passes & fails but also guides the operator in re-calibrating the thermostats of failed units. These units are then immediately re-tested by the system, thus reducing handling.

The test fixtures are made of phenolic to withstand the high temperatures involved.

The function of this chamber is to test the reliability for power supplies for the telecommunications industry.

The burn-in process is carried out at 85 Deg. C with the units under test powered up and loaded with short circuits.

Designed and built for BCM Corporation (M) Sdn Bhd in Kulim, Kedah.

Designed to accept appliances of various makes & sizes, the purpose of this machine is to flex power cords at various angles to the vertical with a 1 kg weight attached to them.

The flexing is carried out while rated current and voltage are applied to the appliance under test. Any break in the conductors of the power cord will immediately be signalled by the machine.

Able to discharge a 75/150 Amp output current, this tester is used for testing relay contacts. A timer and digital counter control the on / off timing of the relay under test. Users can monitor the output current by connecting an oscilloscope to the Current Monitor Terminals

Total number of blasts is recorded by a counter, so that the user will know the durability of the relay contacts. This unit can test relays with either 12V or 24V coils.

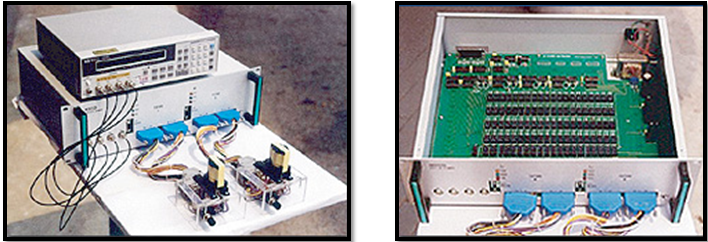

Designed for use with an HP4263B LCR meter, this dual test fixture transformer tester is GPIB controlled and can test transformers with up to ten windings each in 4 wire measurement modes. Tests include inductance, turns ratio, inductance ratio, DC resistance, inter pin shorts & opens.

Other features include programmable test frequencies, test voltages and contact integrity checking. Data logging for SPC purposes is a key feature. Notice the single board construction and almost total absence of wires (except for the power supply transformer).

Using high quality Omron small signal switching relays, this extremely reliable board can connect the HP4263 to perform 4 wire measurements of up to 20 channels (that's 10 windings) per test fixture.

A powerful Windows based program makes it possible to start testing transformers in minutes. Ideally suited to transformer manufacturers, it can test a 10 winding transformer in under 7 seconds.

Complementing the vacuum cleaner hose flexing tester (shown elsewhere) this machine check the hose whereby a current carrying hose has to resist abrasion.

The hose is moved back and forth over a slowly turning abrasive belt with a weight of 1 kg connected to the free end. No exposed wires are to be seen at the end of the test.

PLC controlled system linked to timers for turning on and off a tap switch for instant water heaters. Built for Joven Electric Co. SB (Klang, Selangor).

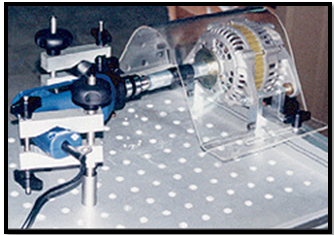

The function of this machine is to apply a constant machanical load to the output side of portable tools such as hand drills, grinders, polishers etc.

For example a hand drill rated at 400W maximum input power has to be loaded until its input power is 400W + 5% for a period of 1 hour, during which the temperature of the motor windings is recorded.

This 3500 kW electronic load (current sink) is used for testing power supplies. It has input range of 1 - 100 VDC and a current range of 0 - 150 Amps.

It has three modes of operation: Constant Current, Constant Resistance and Auto Switching between the two. Built for BI Technologies (M) Sdn Bhd.

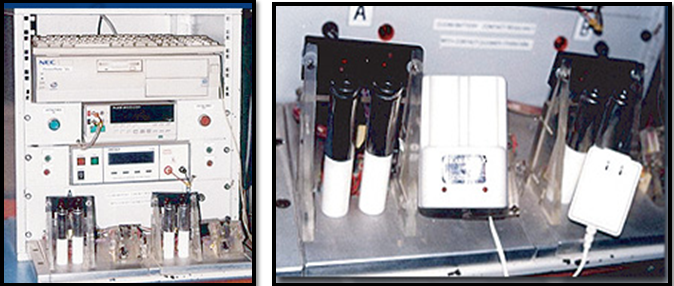

Capable of handling 2 units at a time, the tester tests Hi-Pot, Battery Charging Voltage, Battery Charging Current and LED display functions. The left and right test fixtures ensure that handling time is not a consideration in the cycle time thus ensuring maximum throughput & productivity. Being PC controlled, the production engineer has access to key parameters and limits.

A powerful software written in Visual Basic 5 controls the tester hardware and provides excellent MIS (Management Information Systems) type features for carrying out statistical functions for production staff and line output monitoring for management of quality and productivity. Shown in the middle is the battery charger to be tested. Notice the two cavities where either one or two batteries can be inserted for charging and the red LEDs at the bottom indicating the charging status of each battery.

On the left and right of the picture are the two test fixtures. For each fixture there are two vertical rods constructed of teflon with a nickel plated copper sheath on the top. These represent the batteries to be charged and are fixed to the base of the test fixture. The charger to be tested is fitted on to these rods, thus eliminating the need for the operator to handle individual batteries. Appearing as two red dots above the vertical battery rods in the picture are sensors that monitor the on / off conditions of the LEDs in the charger under test.

This RS-232 50 Channels Multiplexer is used by Telekom Malaysia Berhad to monitor the alarm status of certain channel in their SDH systems. Amount of channel are depending to the customer need. RS-232 Multiplexer Features :

This is a crush stress testing machine designed to stress specimens by crushing them at a fixed rate of travel. The crush force is held steady it has reached the preset limit.

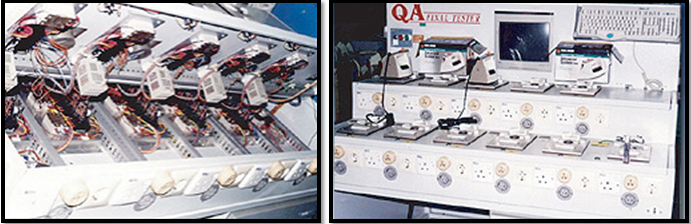

This tester was specially designed for Outgoing Quality testing. Besides performing the usual functional testing, it tests hi-pot breakdown, insulation, input power and leakage current. Able to test up to 11 units at any one time, it is controlled by a PC running a program written in Visual Basic 5 on a Windows '95 platform.

Full data logging and reporting, and the ability to be networked provides the QA Manager with up to the minute information about outgoing quality without having to leave his office. SPA (Statistical Process Analysis) is built in as a standard feature. Shown are temperature measurement sub assemblies wired into the QA test system (shown elsewhere).

Temperature controlled non-contact sensing heads measure the temperature of the units under test to an accuracy of 1° Fahrenheit.

The relays and SSRs shown in the middle of the picture control the switching of power to each unit under test.

This system was designed for the Fishermen's Association of Kuantan. The first of it's kind in Malaysia, the system works as follows : As fish is offloaded at the jetty, the details of the fish such as species, weight, grade are logged into the electronic database of the system.

When the auction starts, buyers take their places at their preassigned buyer stations. The details of the fish on auction are then displayed on the wide screen monitors, together with the offered prices. If there are no buyers at that point, the price is reduced (this method is called a 'Dutch Auction').

When a buyer accepts the price on display, he presses a button on his console, thus identifying himself to the system. Cash bills and other documentation are then printed by the system on demand.

This tester is used to check the quality of automatic recoiling cord reels by extending the cord out of the appliance under test (in this case the red vacuum cleaner on the left) and then letting it recoil under controlled conditions as specified in the IEC 335-1( 3rd edition 1991-04), clause 22.16.

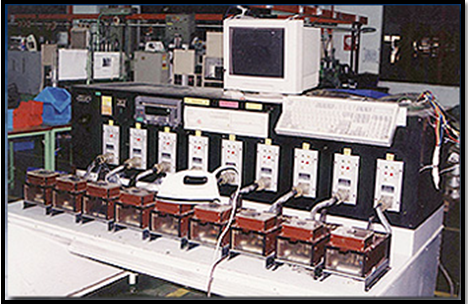

This tester allows you to do reliability testing of 8 units of instant water heaters simultaneously. Controlled by a timer, the water flow to each heater is turned on and off for a few thousand cycles, ensuring maximum mechanical and electrical stress for the unit under test. At the side of the test rack is the control and monitoring panel. Users can set the on/off time, monitor and record the cycles from this panel. Each test station includes an acrylic flow meter, pressure gauge, MCB and indicator lamps.Water Heater Reliability Tester Features :

Swivel connections allow an appliance to be twisted around continuously without having its power cord ending up its a tangled, twisted mess. These types of connections are normally found on hair curlers and hair dryers.

To gauge the reliability and safety of swivel type connections, this tester will exercise the swivel connection by rotating the appliance in a clockwise and anti-clockwise manner while the power cord is loaded with a pre-determined weight.

This tester verifies the correct ratio between the primary and secondary windings of the transformer under tester. This tester has been designed for very low inductance toroidal transformers which are used in small signal circuits.

The number of turns can be set by adjusting the trimmers inside the tester. This tester is designed to test 2 secondary windings of a transformer at one time.

Designed primarily to flex the hoses of industrial type vacuum cleaners, this machine tests the safety of current carrying hoses which may be exposed to numerous flexings (e.g. a vacuum cleaner which has an/off switch in the handle).

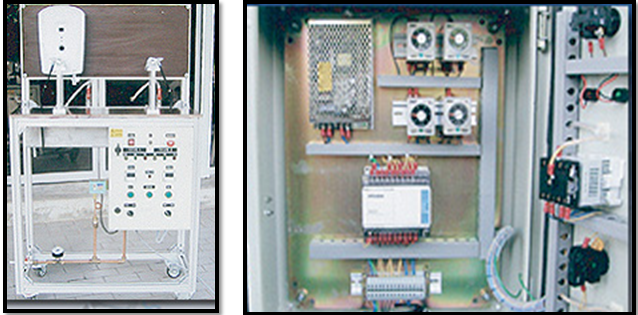

Wherever the powerful computing functions computing of a PC are not essential, PLCs are employed in our systems.

Pictures show an OMRON COM1 PLC controlling among other things a Mitsubishi Servo Motor System.

PLC controlled system can be linked to PCs to effect a distributed control system.

Designed, fabricated and installed for Honda at Melaka. This system records the vibration waveforms from a drive shaft tester.

Waveforms are captured dy the DSO and downloaded to the PC. Captured waveforms are stored in a manner which makes them easily retrievalbe using the serial number of the drive shaft.

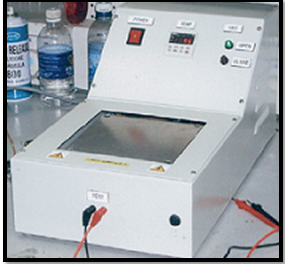

Designed for MTS Fiamma for confirming the cut-off temperature for thermal swiches used as safety devices in water heaters.

This system consists of a temperature controlled hot plate on which the devices to be confirmed are placed. After a minutes of heating the divices are measured with the built-in continuity tester to ensure that they have switched from closed to open

Shown above in an actual production line is Malaysian Test Equipment's fully automatic tester for testing indoor units of split type air-conditioning systems. Supplied to an internationally renowned manufacturer of air-conditioners, this system can test units of up to 15 HP. Safety tests, functional testing, data-logging and extreme versatility have made this system an indispensable part of the manufacturing process.

The software and hardware were designed for ease of configuration - allowing the tester to be used for almost any model & make of air-conditioners. Barcode scanning allows all units tested to be logged with respect to their serial numbers. Other information includes motor serial numbers, vibration levels, input currents at different settings and control signals status.

A simple operator interface makes training of operators a snap, while training of engineers to program the system for different models in production is greatly enhanced with the point-and-click interface.

Designed to test the reliability of various types of switches, this tester comes with fixtures and test programs for toggle, push button, slide and cord operated switches.

A programmable stepper motor controls the amount of travel for each actuation of the switch under test. This allows switches of various sizes to be tested.

The extended universal joint allows the specimen to be placed in an oven for elevated temperature testing.

These loads were designed for SIRIM to enable them to test switches under conditions which are most likely to be seen by various types of switches.

The loads are capable of drawing currents of Power Factor 0.3 and 0.6 in a range of 6 to 20 Amps in accordance with clause 18.1 and 19.1 of IEC60669 (1998).

This machine will repeatedly lift cordless irons from their base and replace them back in order to check the quality of the power output connector in the base. The lifting force is effected by electro-pneumatic means.

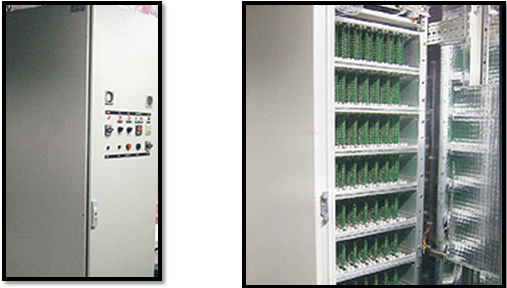

Designed, built & installed for Matsushita Refrigeration Industries (M) Sdn Bhd in Malacca, these 8 racks have been designed to perform a multitude of 'worst case' tests on refrigerator compressors meant for the local and export markets.

Again, simple operator interfaces make the system operatable by semi-skilled employees while complex programming algorithms run in the background to ensure all critical parameters and performance functions of the products under test are captured and logged in an easily retrievable format.

Steam buttons on steam producing irons are exercised for reliability by this machine. Engineered to accept various sizes of steam irons, the number of cycles of steam button operation can be pre-programmed from the front panel.

Used to test electric irons which have a built in automatic shut off feature, this tester utilizes a solid state AC source to generate high frequency test voltages in order to reduce the testing time of such irons.

Shown here in an actual factory environment, the tester combines mechanics, pneumatics and electronics to perform its functions. In the picture on the right, handling of the electric iron is being simulated by the upward movement of the test fixture.

Safety of the operator is a prime consideration in all our designs. In this tester, emphasis was placed on operator safety and ease of use. No moving part in this tester can compromise the safety of the operator.

Proudly designed, fabricated and programmed in Malaysia by Malaysians, it can test up to four irons at any one time.

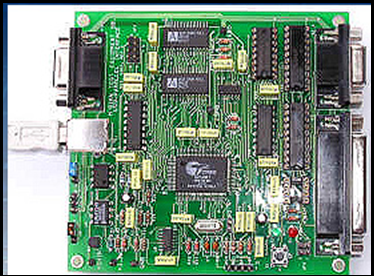

This is our USB to Parallel & Serial Interface. Designed primarily to control our test systems, this interface can also be used as a general purpose Input / Output unit.

This board is suitable for anyone who needs to control external devices such as relays, leds, buzzers etc through a USB port on the PC or read the status of switches, sensors and other input devices.

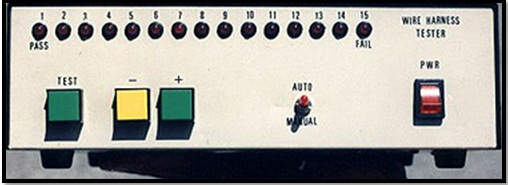

This tester has been designed to test wire harness assemblies for opens, shorts and cross-overs. It has a 'self learn' feature, where a known good wire harness is plugged into the tester during power up. The system exercises and memorizes this harness' connections and then uses these as a reference when testing production units.

Alternatively, it can be set up manually and for serial testing of each wire in the wire harness under test for testing with a hand-held probe.

This multi-axis built robot was installed and programmed to enable the costomer to perform reliability testing of refrigerator doors, washing machine lids, rice cooker lids etc.

Various safety standards require that parts are frequently handled by the end user need to be exercised tens of thousands of times to ensure that they will not become hazardous.

Designed and built for an electric iron manufacturer, this machine calibrates thermostats mounted on sole plates without actually heating them up. An unique sequence of calibration steps ensure repeatability and uniformity between thermostats.

Additional features include the ability to distinguish the hysteresis action of thermostats. Defective thermostats (those that do not exhibit hysteresis) are rejected by the machine.

Once calibrated by this machine, the sole plate can be tested immediately without requiring any further adjustments.